Magnetron sputtering has become an indispensable vacuum coating technology in many industries and fields of application. This deposition method is used to provide a multitude of materials and substrate with optical, mechanical, or electrical properties for the desired application.

The Manfred von Ardenne Research Institute and its successor VON ARDENNE GmbH have been instrumental in the development of this technology over the last decades.

In this short series of articles, we would like to introduce the most important milestones to you as well as our contributions to the advances in magnetron sputtering.

The early days of sputtering

The phenomenon of sputtering was mentioned for the first time in 1852 by Sir William Robert Grove. He had observed that metallic deposits occurred on the inside of a discharge tube when he examined the conductivity of gases with a direct-current glow discharge.

Magnetron sputtering itself, that means the atomization of solid cathodes or the target material by bombarding them with gas ions in vacuum, can be traced back to the Dutchman F.M. Penning. In 1936, he was the first to describe a coating device with a cathode and an anode supported by a magnetic field.

Between the late 1960ies and the early 70ies, P.J. Clarke and J.S. Chapin almost simultaneously developed the first sputtering sources. Clarke positioned the cathode around the anode in a ring-shaped way, whereas Chapin chose a planar setup and thereby invented the planar magnetron. However, these sources were not suited for industrial use due to their low ionization and coating rates. A.M. Dorodnov followed a different approach and introduced a closed, ring-shaped magnetic arrangement for plasma accelerators for the metallization of surfaces.

The first ignition of a magnetron at VON ARDENNE

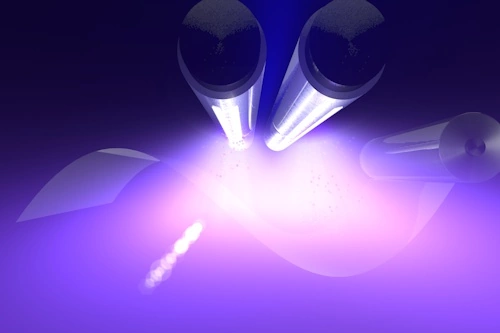

In 1974, almost at the same time and without any knowledge of Dorodnov’s work, a group of scientists of the Manfred von Ardenne Research Institute in Dresden chose a similar setup: a magnetron with a closed ring gap discharge close to the cathode. This arrangement enabled a considerably higher ionization of the process gas and much better coating rates. The video shows a replication of this setup.

Not even a year later, the institute presented the first commercial magnetron: the Plasmatron PPS-5A (see picture), which could be operated with a capacity of five kilowatts at 500 volts. It could reach remarkable sputter rates of 0.7 grams per minute when copper was used as a target material.

This development was the first step for VON ARDENNE in paving the way for industrial vacuum coating as it put the company in a good position to become one of the leading providers of magnetron sputtering technology.

In the next article, you will learn how microelectronics enabled the breakthrough for the sputtering technology in the 1980ies and what VON ARDENNE contributed to that.