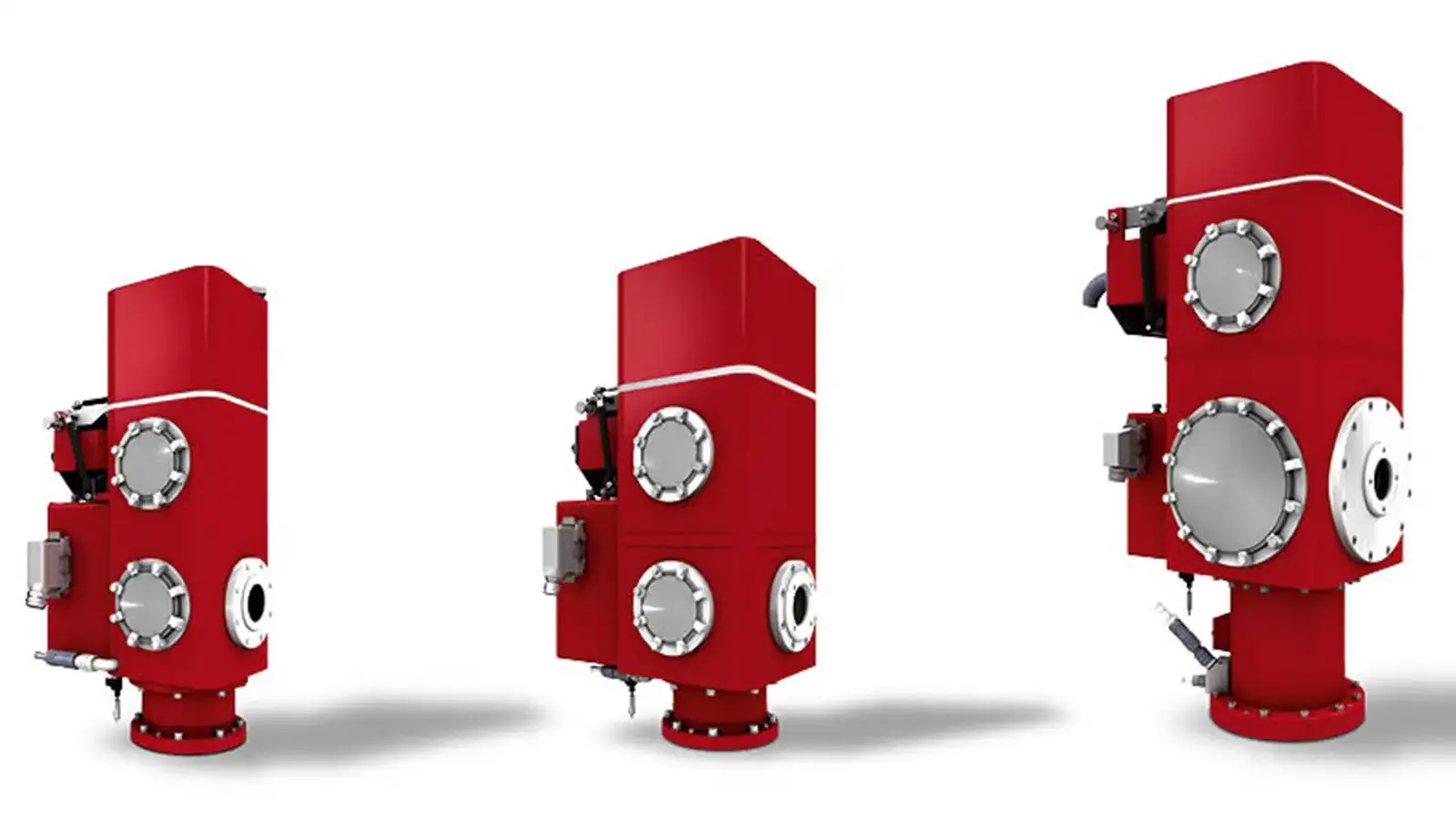

With the EH150V, EH 300V and EH800V electron beam guns, we offer you components for high-performance applications. This applies to melting and refining as well as evaporation of metals, alloys and composites.

As our customer, you will benefit from the comprehensive know-how we have acquired through more than 400 electron beam systems in operation all over the world. It includes beam generation, generator technology, beam focusing and digital beam deflection processes. These processes enable dedicated power distribution and timing control on the area impacted by the electron beam.

At our Electron Beam Technologies Development Center, we are striving to continuously improve our key components. Here, we also manufacture and test our high-quality electron beam guns.

Reliable & proven

as a series product in many applications

Modular design

with clear interfaces for plant integration

Simple handling

and easy maintenance

Technical Data

Subject to change without notice

due to technical improvement.

Substrat

Material: Flachglass

Dicke: 2 mm bis 19 mm

Beschichtungsfläche

GC330H: bis zu 3300 mm x 7800 mm (Super Jumbo)

GC280H: 2800 mm x 5000 mm

GC254H: 2540 mm x 3810 mm

Taktzeit

GC330H: < 28 s

GC280H: ≤ 25 s

GC254H: < 18 s

Basisdruck in Sputter-Kammer

≤ 5 x 10-6 mbar

Stromversorgung

Anforderungen: zwischen 0,5 und 5 MVA, abhängig von Anwendung und Durchsatz

Hauptanschlüsse: 400 VAC, 50 Hz oder 480 VAC, 60 Hz